Search

Our priorities mirror India’s Viksit Bharat goals

VG Sakthikumar, Chairman and Managing Director, Schwing Stetter India, speaks on the growth priorities for the Indian market in the next three to five years.

Future Excavated

India’s infrastructure boom is unearthing a new era of smart, sustainable, and connected hydraulic excavators powering tomorrow’s construction landscape.

Metro Rail sustainability suffering from affordability & connectivity

An affordable fare structure & an efficient last-mile connectivity are vital for Metro Rail

What’s Ahead in CE Manufacturing Sector

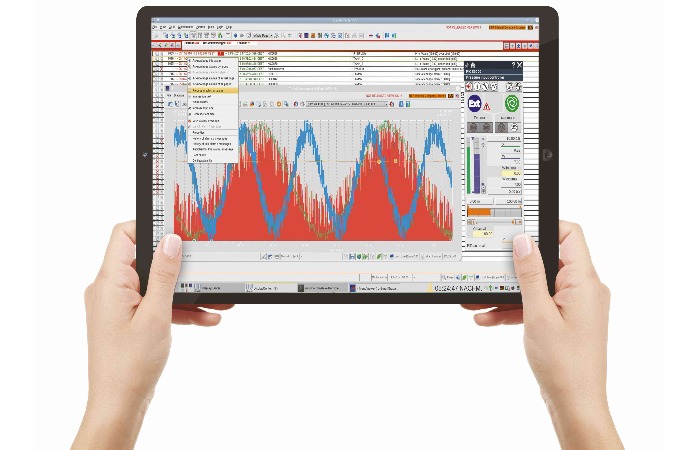

Construction equipment OEMs are aimed at intensifying products with the latest technologies adding higher productivity, lower maintenance, easy operations, and remote connectivity.

What’s Ahead in CE Manufacturing Sector

The article is authored by Himanshu Sharma, Head – Marketing & Corporate Communication, B&R Industrial Automation.

We are a preferred automation partner for market leaders

B&R India has established seven offices in major cities of India and has expanded its Pune office space to match the growth.

Rs 200 billion projects initiated in Mumbai

Prime Minister Narendra Modi initiated projects of about Rs 200 billion for Mumbai. The three metro corridors initiated by the Prime Minister are 9.2 km Gaimukh to Shivaji Chowk (Mira Road) Metro-10 corridor, 12.7 km Wadala to Chhatrapati Shivaji Maharaj Terminus Metro-11 corridor and the 20.7 km long Kalyan to Taloja Metro-12 corridor.

The Eleventh Hour Is Here!

By 2025, the construction market in India is expected to emerge as the third-largest globally.

Pioneering Growth

Traditionally known for aerospace, engineering and IT, Bengaluru is fast emerging as a construction equipment (CE) hub in India with major players expanding their base in the city.

High temperature and water resistant greases are need of the hour

The government is focusing more on developing infrastructure in India for the overall growth of Indian economy. Projects like smart cities and bullet trains require more of innovative technologies and equipment.

Construction World Annual Awards 2017

Foundation of Infrastructure Research Studies Training (FIRST) hosted the 15th CONSTRUCTION WORLD Annual Awards at ITC Grand Central, Parel, in Mumbai.

NCC buys Liebherr Telescopic Crawler Crane

Liebherr has delivered a new LTR 1220 telescopic crawler crane to NCC Ltd Hyderabad for its Nagpur metro project. In this project, the crane hoists girders for the two new metro lines which have a total length of 38 km, thereby the pick-and-carry characteristics of telescopic crawler crane are a great advantage. Liebherr is convinced that the use of such a crane, first time in India, will give a big opening to this technology.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com